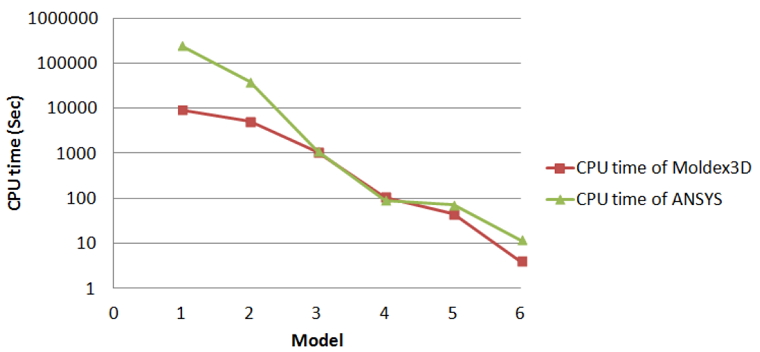

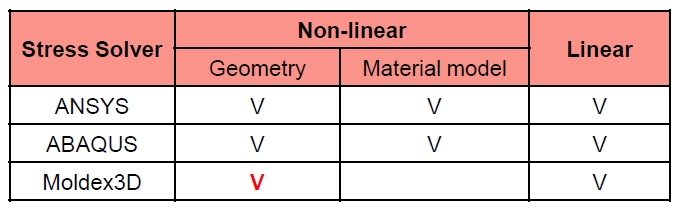

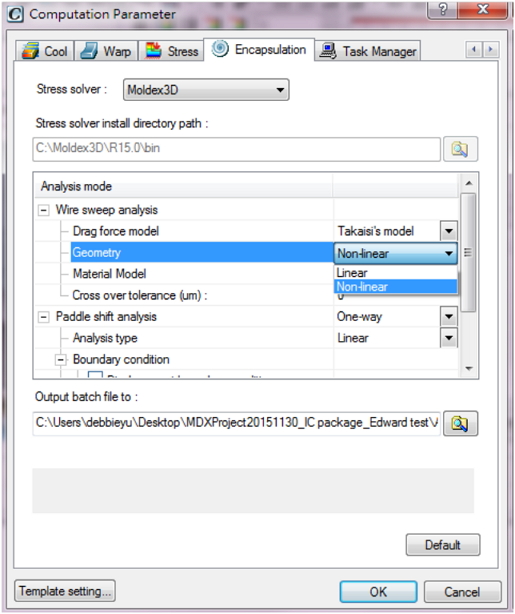

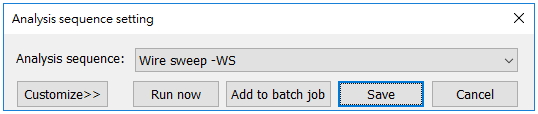

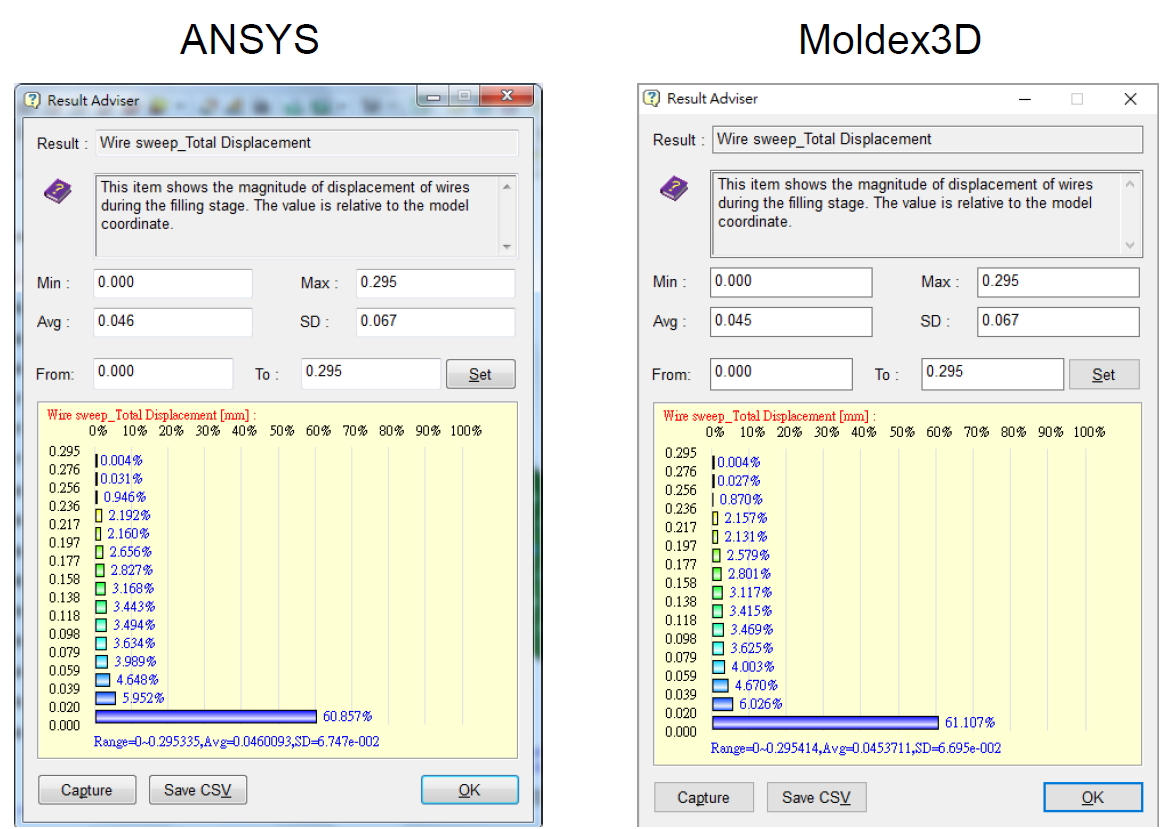

To predict the viscosity-induced wire deformation during chip encapsulation, Moldex3D IC Packaging Module adopts linear solver as default because the small deformation simulation is always fast and quick for preliminary Wire Sweep analysis. However, more common wire sweep is based on huge deformation, so the sweep result of linear analysis can be over-estimated. Moldex3D supports the option of Non-linear analysis to improve wire sweep prediction for more accurate results. The wire sweep analysis also supports linking with ANSYS and ABAQUS solvers for non-linear consideration of both geometry and material property. For now, Moldex3D IC solver also considers the non-linear geometry in analysis, while it is still linear for wire materials. The stress solver capacity of wire analysis is shown below, and the following will show the workflow and performance of Wire Sweep analysis with Moldex3D solver. Step1. In Computation Parameter of IC project, select Moldex3D for Stress solver under the Encapsulation tab.  Step2. Select Non-linear for the Geometry in the wire sweep analysis and click OK to finish the computation parameter setting of Encapsulation. Step3. Launch the Analysis sequence setting after all analysis settings are finished, and make sure the Wire Sweep analysis continued from Filling analysis. Click Run now to perform the calculation. Note: Wire Sweep analysis requires filling analysis to be completed first  The validation result shows the distribution of Wire Sweep has good agreement between ANSYS and Moldex3D non-linear solvers, meaning, the wire sweep is mainly affected by geometric non-linearity. Furthermore, the Moldex3D solver spends much less CPU time for simulation, especially for large wire counts.  Roadtrack Tyre,Truck Tire,Bus Tires,Light Truck Tire WINMAX AND MACROYAL TYRE GROUP , https://www.glamorcorp.com

Stress solver capacity of wire sweep analysisStep-by-step to prepare the non-linear analysis setting in Moldex3D

Extended analysis and result interpretation

Model

Wire Numbers

CPU time of Moldex3D

CPU time of ANSYS

1

21714

9185

242966

2

4491

5153

38606

3

1075

1054

1145

4

76

106

91

5

64

45

71

6

16

4

12